With the advancement of the Internet of Things and the maturity of RFID technology, its application has penetrated into all aspects of production and life. In the core field of intelligent manufacturing, RFID tags, with their irreplaceable characteristics, realize real-time production data and lean management processes, completely changing the traditional production management model. The particularity of intelligent manufacturing environment, such as metal interference, high temperature oil pollution and high speed process, determines that the performance requirements of RFID tags are much higher than those of conventional applications. This not only involves the material, size and sensitivity of the label, but also requires it to have industrial-grade high temperature resistance, acid and alkali corrosion resistance and almost unlimited reading and writing times to ensure seamless access to production data.

At the early stage of RFID technology development, it is difficult to balance the performance and size of tags due to the limitations of antenna design and chip technology. In order to ensure sufficient read and write performance and stability, tags are often designed to be relatively large, resulting in severely limited application scenarios; and in order to pursue miniaturization and flexibility, it is often necessary to make significant sacrifices in performance. This dilemma of "one out of two" has once become a key bottleneck restricting the popularity of RFID technology.

Now, with breakthroughs in microelectronics and antenna design, these long-standing problems have been fundamentally solved. Modern RFID tags successfully find a delicate balance between performance and size-not only to achieve stable and reliable read and write performance in a smaller form, but also to meet the application requirements in complex environments.

Below I will take RFID PCB tags as an example to describe the application advantages of small size PCB tags in intelligent manufacturing:

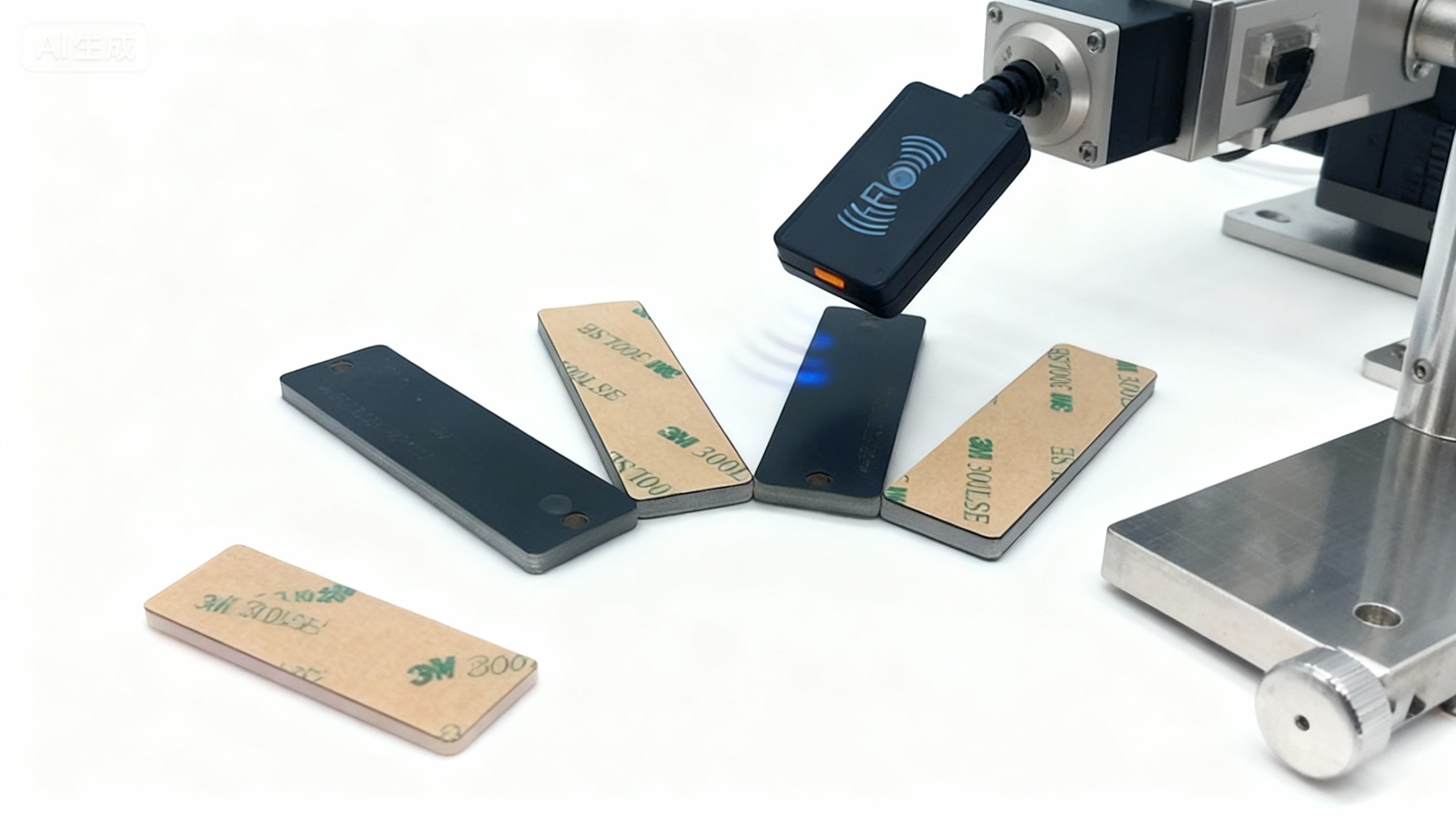

Radio frequency identification (RFID) technology is concentrated in FR4 materials of only a few millimeters in size to create small size RFID PCB tags that are resistant to metals, high temperatures, chemicals, and high read and write accuracy, perfect for complex production environments. From automotive assembly lines to precision tool management, these labels are reshaping the efficiency and transparency of smart manufacturing.

The core advantages of small size RFID PCB tags lie in their miniaturized design and strong environmental adaptability. These tags are typically only a few millimeters to a centimeter or two in size, making them ideal for insertion into tight spaces such as tools, fixtures, or circuit boards without affecting device functionality. Available in FR4 or ceramic substrates, they have IP68 protection, meaning they are completely dust and water resistant and stable to extreme conditions. For example, in the high-temperature welding workshop of automobile manufacturing, the label can withstand temperatures up to-40-150°C, resist chemical solvents and oil, and ensure data integrity. More importantly, these tags have excellent anti-metal properties, through the built-in ferrite shielding layer, overcome the common signal interference problems of metal surfaces, even if attached to metal tools or engine parts, read and write distances of up to 1-5 meters, in accordance with ISO 18000-6C standards (UHF, 860-960 MHz). This high-precision reading and writing ability is especially critical on complex production lines, accurately identifying each component and avoiding human error.

In intelligent manufacturing, the application scenarios of small size RFID PCB tags are extensive and efficient. For example, in tool lifecycle management, factories embed these tags for each precision wrench or drill bit to track usage and maintenance status in real time. In the in-process tracking of production lines, these labels record the processing status of each circuit board or component, from soldering to assembly traceability, avoiding the problem of traditional bar codes failing due to high temperature or stain. In automated robot control scenarios, tags provide precise positioning data for the robot to guide the robot arm to grab a particular fixture or part. These applications benefit from the label's high read/write accuracy and IP68 protection, ensuring reliability in dust, moisture or high temperature industrial environments.

The automotive industry is another big arena for small size RFID PCB tags. In recyclable transport vehicle management, these labels are embedded in pallets or metal containers to track their flow path through the supply chain. The label's metal resistance and high temperature resistance allow it to maintain performance through repeated cleaning and high temperature sterilization processes. In engine assembly tracking, tags are embedded into engine components, recording production lot and quality data for each part, and can be read stably even in high temperature and high pressure assembly environments. This high precision and durability makes RFID PCB tags a key part of the intelligence of the automotive industry.

Looking ahead, the application of small size RFID PCB tags will be further expanded. With the rise of wearable devices and avionics, the miniaturization and high temperature resistance of these tags will enable them to be embedded in smaller smart devices for accurate tracking and data management. They not only improve the efficiency of intelligent manufacturing, but also provide data-driven decision support for enterprises. If you want to introduce efficient and reliable tracking solutions into production, small size RFID PCB tags are undoubtedly the best choice. Contact Guangdong Xinye Smart Label Co., Ltd. to explore customized RFID tags and open a new chapter in intelligent manufacturing!