High temperature resistant ceramic RFID tag (hereinafter referred to as ceramic RFID tag) is a passive or semi-passive RFID solution designed for extreme environments, with excellent high temperature resistance (up to 200°C), chemical corrosion resistance and anti-metal interference characteristics, mainly used in industrial manufacturing, automotive, medical and oil and gas fields.

The electronics manufacturing industry, which is at the heart of the global high-tech supply chain, faces tracking challenges from high-temperature processes such as soldering, coating and baking. Traditional RFID tags are prone to deformation or signal attenuation in high temperature environments, resulting in data loss and low production efficiency. High temperature ceramic RFID tags, as a radio frequency identification technology resistant to extreme environments, play a key role in the electronics manufacturing industry. Encapsulated in ceramic materials, these tags are able to withstand temperatures from -40 ° C to 200°C while maintaining signal stability and data integrity, with ceramic materials as the core packaging technology to support long-range reading in the UHF band (860-960 MHz).

The core of high temperature ceramic RFID tag lies in its material composition and RF design. Guangdong Xinye Intelligence Lable Co, Ltd.'s high temperature RFID ceramic tag size, color, reading distance can be customized, light weight, flexible installation mode, IP65 protection level, resistance storage temperature-40 °C to 200 °C, working temperature-40 °C to 80 °C. Ceramic packages (e.g. polyimide or special ceramic composites) provide additional protection against oxidation and corrosion while embedding H3 chips (customizable), supporting EPC 96bits and USER 512bit storage (depending on the chip), conforming to ISO 18000-6C standards, and frequency range 902-928MHz.

Technical features include:

Frequency and protocol: mainly UHF (902 - 928 MHz), reading distance varies with different readers, fixed machine reading distance can reach several meters, handheld reading distance is about 1 - 5 meters, in line with ISO/IEC 18000 - 6C standard, anti-metal design supports metal surface applications.

Anti-metal design: overcome metal interference through ferrite shielding layer, achieve stable reading of metal surface, suitable for metal component tracking in electronic manufacturing.

Passive power supply: passive chip from the reader antenna field to obtain energy, life up to 10 years or more, suitable for high temperature no power environment.

These features ensure data integrity during soldering or coating processes in electronics manufacturing, and flexible mounting improves adaptability

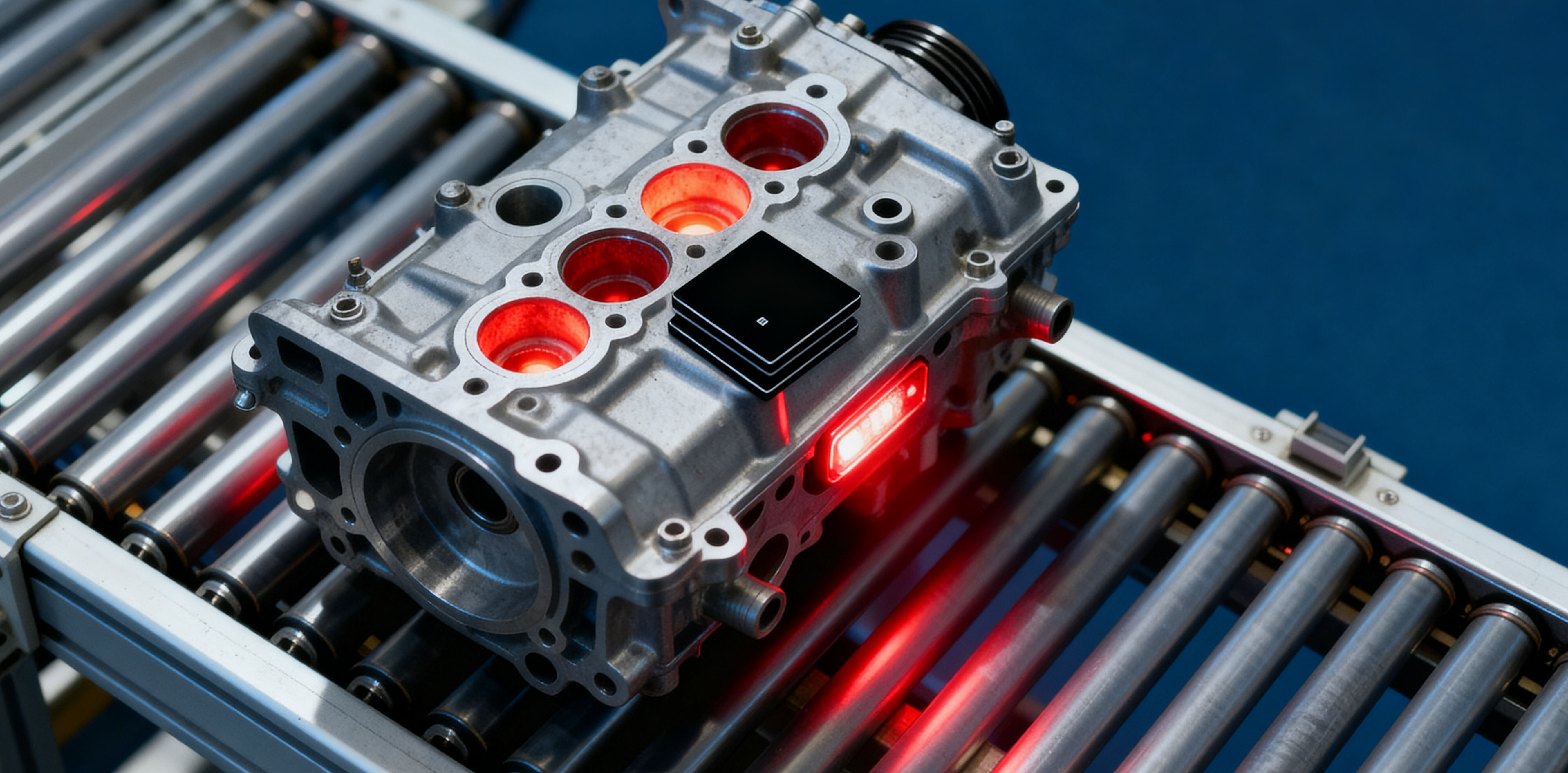

The application of high temperature ceramic RFID tags in electronic manufacturing focuses on full life cycle tracking, improving efficiency from component production to finished product assembly.

In semiconductor and circuit board manufacturing, labels are embedded in metal housings or attached to components, small labels are suitable for tracking miniature components in avionics, such as sensors and circuit boards, IP65 protection class ensures sensitivity in high temperature and high pressure environments (e.g. 200°C soldering)

In the warehouse, ceramic labels withstand high temperature storage environments (such as heat treatment areas), and integrated sensors monitor temperature changes.

In addition, high temperature tags can also be used in wearable device manufacturing, tracking batteries and display components, storing record batch information, and improving quality control efficiency.

Tool management and industrial asset tracking management also often use UHF tags, such as wrenches or test equipment in factories. Flexible mounting of fixed readers and portability of handsets improve asset management efficiency.

The application of high temperature ceramic RFID tags in electronic manufacturing tracking marks a major advance in RFID technology. Through heat-resistant ceramic packaging and UHF protocol support, real-time tracking in high temperature environments is realized, improving efficiency and quality control. Kindly contact and ask for detail!