According to the requirements of the national standard "liquefied gas cylinders" (GB 5842-2023), each cylinder must correspond to a cylinder enamel label when it leaves the factory, and it must be installed on the cylinder cover by welding to be used for the permanent "cylinder ID card" that the cylinder leaves the factory, implementing a bottle of one code, a bottle of one file, scanning identification, and dynamic tracking management.

Establish detailed original cylinder files for each cylinder in the computer management system, including all technical quality information such as cylinder manufacturer, manufacturing date, model and specification, pressure rating, manufacturing number, inspection date, etc. The handheld barcode data collector is used to scan, identify and register the information of gas cylinders one by one in each link of receiving and dispatching, pre-filling inspection, filling registration and post-filling re-inspection of gas cylinders. If defective gas cylinders, expired gas cylinders or gas cylinders with inconsistent media are found, they can be identified and rejected in time.

Why Choose to Use Metal-ceramic Cylinder Bar Code Tags (Enamel Labels)?

*Detailed asset information of gas cylinders: the quantity of gas cylinders of various types in use, the remaining useful life, and the quantity of abnormal scrapping (early scrapping before the endof life) of gas cylinders.

*Workload assessment of operators, statistical analysis of different processes, different teamsand the working conditions of each operator.

*Quality cause and responsibility tracing. When safety and quality problems occur, the responsible link of the accident and the specific person directly responsible can be tracedcorrectly and timely according to the operation records of the computer.

*Tracking of suspected defective gas cylinders. For suspected gas cylinders found to havepotential quality and safety hazards, they can be tracked and recalled in time through the sendingrecords of gas cylinders.

*Prevent the loss of high-quality gas cylinders. By tracking the flow direction of high-quality gascylinders, it can be avoided to falsely claim high-quality gas cylinders in the process of receivingand dispatching.

*Prevent and reduce quality and safety accidents of gas cylinders. Through strict traceableoperation records, the responsibility of operators can be rigidly restrained and improved, andquality and safety accidents caused by human factors such as negligence can be reduced.

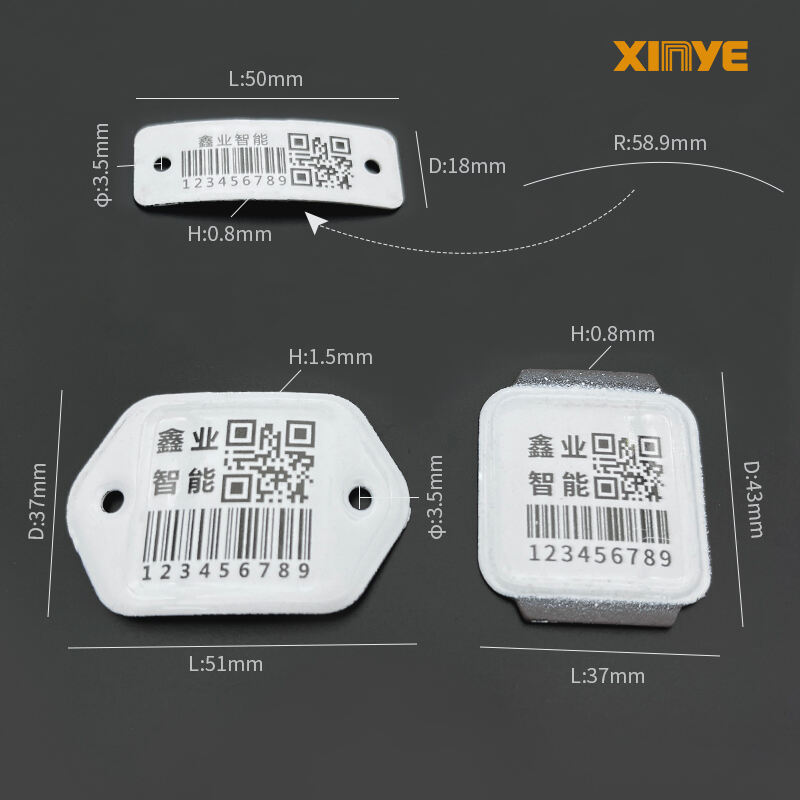

Xinyetag supply Industrial gas cylinder enamel label and LPG cylinder enamel label,the specific size is shown in the following figure.

Fig.1 schematic diagram of overall dimensions

Fig.1 schematic diagram of overall dimensions

Table 1 Detailed dimension requirements for enamel labels

| Product Name | Label length /mm | Label width /mm | Label thickness /mm | Hole diameter /mm |

| The beveled edge gas cylinder enamel label | 51 | 37 | 1.5 | 3.5 |

| Enamel labels for industrial gas cylinders | 50 | 18 | 0.8 | 3.5 |

| The semi-enamel labels | 37 | 43 | 0.8 | - |

Industrial gas cylinder enamel label and LPG cylinder enamel label features

Industrial gas cylinder enamel label and LPG cylinder enamel label features: Enamel labels are barcode labels generated on a high-strength alumina engineering ceramicsubstrate by a high-temperature glazing process. The barcode symbols are well protectedbyatransparent high-temperature ceramic glaze, and the ceramic barcode can withstand extremelyharsh environments such as acid, alkali, salt, fog, sunlight exposure, and even flame roastingfor a long time. The excellent properties of the ceramic barcode perfectly meet the requirementsfor permanent automatic identification of gas cylinders, and the basic situation of the commerciallyavailable ceramic barcode gas cylinder identification plates that have undergone mass durabilitytests is as follows:

1. Base material: stainless steel

2. Surface coating material: enamel glaze

3. The size and shape of the label plate can be customized according to user requirements.

4. Barcode parameters: one-dimensional barcode, two-dimensional barcode, barcode format

5. Resistant to high temperature (up to 1000°C or more), acid, alkali, salt, fog corrosion, andorganic solvent cleaning

6. Resistant to vibration and impact, with good mechanical strength This label is made of stainless steel, glazed enamel on the surface, and fired at high temperature. Enamel labels can withstand acid, alkali, salt, fog, sun exposure and even the extreme harshenvironment of flame barbecue for a long time. Meet (GB 5842-2023) national standard.

Semi-enamel label features:

Enamel Label Installation Method

Enamel labels for industrial gas cylinders The adhesive bar code with plastic frame is mainly used on the dissolved acetylene gas cylinder. When installing, just remove the protective film on the back and press the bar code on the cleansurface of the gas cylinder with manual fingers. This installation method is firm and reliable, unless deliberately removed by artificial auxiliary tools, it will not peel off by itself. The bar codeitself and the adhesive layer are resistant to corrosive solvents or gases from working processessuch as acetone. In the seamless cylinders (such as oxygen, hydrogen, nitrogen cylinders), riveting and similar tothe dissolved acetylene cylinders of the two installation methods, in the early bar code installationwork mainly used in the seamless cylinder neck ring holes, and then riveted fixed with rivets. Since the collar of the cylinder is separated from the bearing part of the cylinder body, punchingholes on the collar will not affect the bearing capacity of the cylinder, and will not have adverseeffects on the safety of the cylinder. The main disadvantage of the piercing riveting method is that the installation work of the operator is relatively heavy, and the operation is relatively hard. Thecurrent development trend is that more users want to choose the glue type fixing method.

Xinyetag High-temperature ,metal-ceramic cylinder bar code tags meet the weather resistance requirements under normal logistics environment, including but not limited to: high temperature, low temperature, wet heat, acid andalkali resistance, corrosion resistance, salt spray, etc., the structural appearance and ink, we also providing fully customized solutions - using smart labels to improve safety, optimize operational efficiency, and reduce costs. Choose Xinye Intelligent Label, contact us immediately or visit the official website to get a quote!