In the rapidly evolving modern apparel industry, efficient supply chain management, precise inventory control, and enhanced consumer experiences have become core competitive advantages. RFID (Radio Frequency Identification) tags, as an advanced wireless identification technology, are profoundly transforming the operational model of the apparel industry. From production to sales, RFID tags bring significant efficiency improvements and data transparency to enterprises at every stage.

RFID tags serve as an "electronic ID card" for apparel products, recording the complete lifecycle data from production to transportation, warehousing, and store sales. This technology enables automated and real-time monitoring through non-contact reading, addressing the inefficiencies and errors associated with traditional manual records. The key roles of RFID tags in the apparel industry include:

Full-Process Tracking: RFID tags record the entire journey of a product from factory production, logistics transportation to warehousing, ensuring traceability for every garment. For instance, brands can monitor production batches to optimize supply chain efficiency.

Store Anti-Theft and Management: By deploying RFID gate systems in stores, unauthorized movement of goods is automatically detected, preventing theft while improving security management.

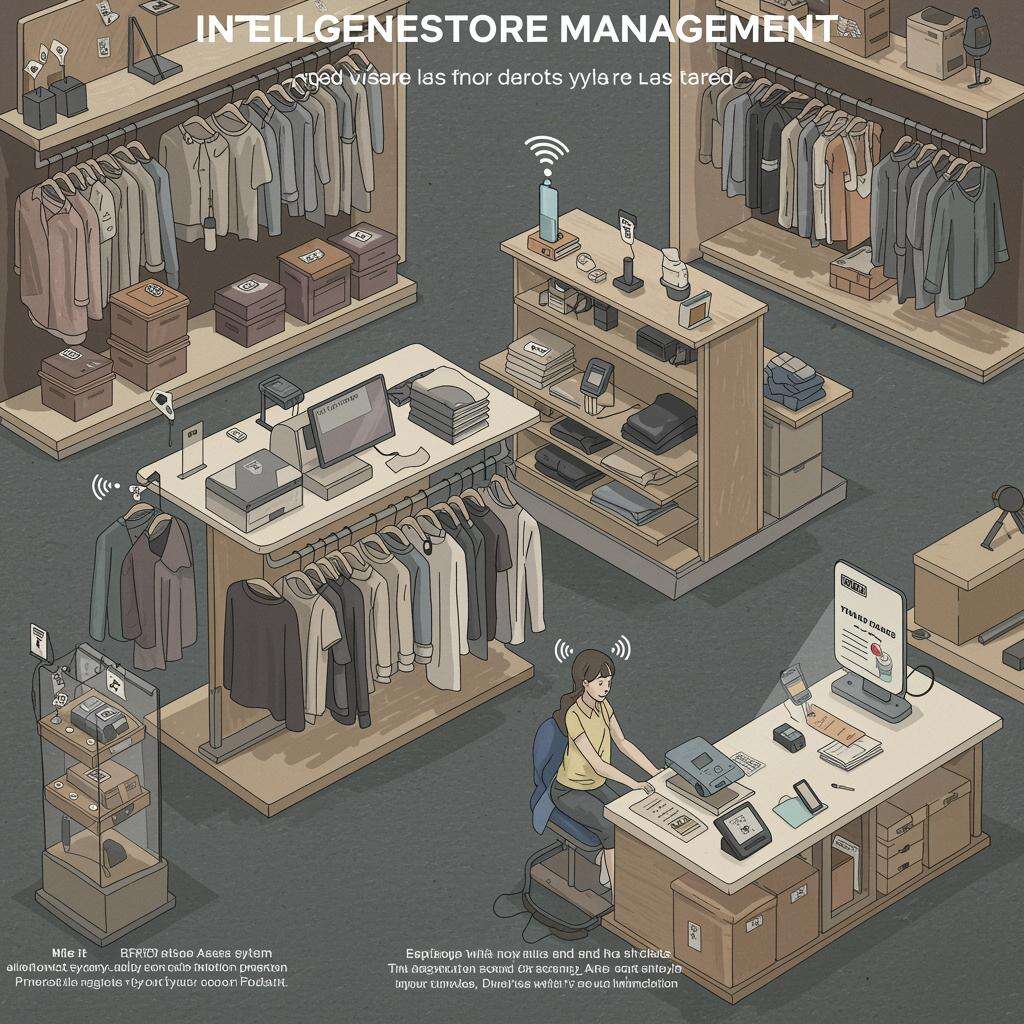

Efficient Inventory Management: Store staff can use handheld devices to quickly locate items, conduct inventory checks, stock counts, and process payments, with bulk data reading significantly reducing operation time and enhancing service efficiency.

Data Monitoring: Headquarters can use RFID systems to monitor sales and try-on data from all stores in real-time, providing data support for inventory adjustments, market forecasting, and marketing strategies.

Brand Verification: Consumers can simply tap their phones on an RFID tag to verify product authenticity via NFC functionality, boosting shopping confidence and enhancing brand trust.

RFID tags are embedded into garments on production lines, recording details such as production dates, fabric batches, and quality information. During transportation, logistics companies use RFID readers to track cargo status, ensuring timely delivery. In warehousing, tags help locate inventory quickly, reducing manual counting time.

In stores, RFID gate systems integrate anti-theft alarms to prevent item loss. Staff can scan shelves with handheld devices to complete inventory and stock counts in seconds, optimizing layout arrangements. At checkout, bulk reading technology allows scanning of multiple items at once, shortening payment time. Additionally, RFID data can analyze popular styles and try-on frequencies, aiding store display adjustments.

Enterprises use RFID systems to centrally manage sales and try-on data across all stores. For example, a brand discovered through RFID that a certain style had a high try-on rate but low sales, prompting a timely promotional strategy that successfully boosted sales. Real-time data also supports regional market analysis, optimizing supply chain allocation.

Consumers can tap an RFID tag with their phone’s NFC functionality to view product details, origin information, and authenticity verification results. This interaction not only improves the shopping experience but also strengthens brand anti-counterfeiting capabilities.

Guangdong Xinye Intelligent Label Co., Ltd. has launched a high-performance UHF apparel tag, operating in the frequency range of 860-960 MHz, equipped with the NXP UCODE 9 chip. The tag offers antenna sizes of 70 x 14.5 mm or 50 x 30 mm, complying with international standards ISO/IEC 18000-63 Type C and ARC certification. Widely applied in the apparel industry for brand protection, supply chain management, and household essentials, this tag provides efficient, anti-counterfeiting, and intelligent solutions for retail enterprises. We warmly invite you to contact us for more information and to explore how these tags can elevate your business.