Xinye's RFID laundry tags are engineered for durability and efficiency, ensuring reliable tracking of textiles through rigorous laundering processes. With resistance to high temperatures and chemicals, our tags maintain performance over numerous wash cycles, optimizing inventory management and reducing operational costs.

Tracking laundry items manually can be a time-consuming and error-prone task. XINYE’s RFID laundry tags offer a solution that makes inventory management easier and more accurate. The RFID technology allows for real-time monitoring of each item, reducing the chances of lost or misplaced linen. By integrating XINYE RFID laundry tags into your laundry operations, you can streamline processes, improve efficiency, and save time while offering a higher level of service to your clients.

Xinye understands that different industries have unique requirements. Our RFID laundry tags are customizable in size, material, and frequency, providing tailored solutions that integrate seamlessly into various laundry operations, enhancing efficiency and accuracy.

XINYE’s RFID laundry tags are transforming how laundromats, hotels, and hospitals manage their linen. By integrating RFID technology, XINYE offers a solution that allows businesses to track items in real-time, reducing loss and improving efficiency. These tags are durable, easy to implement, and compatible with existing systems. Whether you're handling uniforms, towels, or bed linens, XINYE RFID laundry tags ensure accurate tracking, making your laundry operations faster and more reliable.

In industries where textile tracking is critical, Xinye's RFID laundry tags offer a reliable solution. Designed to withstand high temperatures and harsh chemicals, our tags ensure accurate identification and efficient inventory management, reducing losses and improving operational workflows.

Founded in 2008, Xinye is a leading manufacturer of RFID cards and tags, boasting a 30,000㎡ industrial park and a team of over 200 professionals. Over 16 years, we've delivered billions of RFID products to more than 2,000 customers across 100+ countries, serving diverse sectors including transportation, education, retail, and hospitality. Our commitment to quality is evidenced by our ISO9001 and IATF16949 certifications, along with CE, ROHS, and REACH compliance for our products. With over 100 patents, we're dedicated to providing comprehensive IoT solutions and ongoing technical support. Strategically located in Dongguan, near major airports, our state-of-the-art facility features 20+ fully automated production lines and a pioneering Voyantic lab, capable of producing up to 200,000 cards and 50,000 tags daily, all subject to rigorous 100% pre-shipment inspection. Join us in shaping a sustainable future through collaboration and innovation.

Offers long-range identification and high durability, perfect for large-scale inventory management.

Portable design with reliable security, enhancing guest experience in hotels

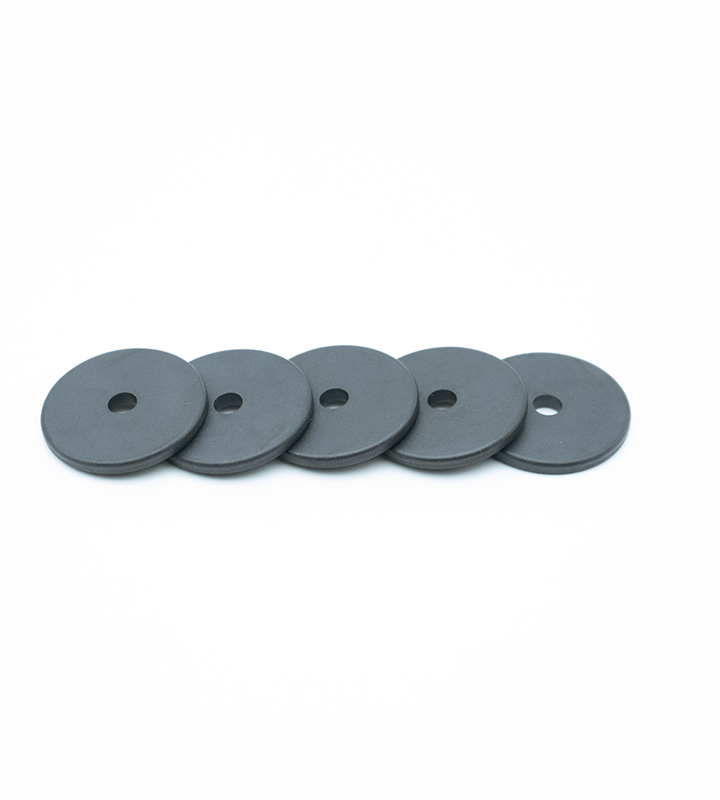

Waterproof and heat-resistant, reusable to reduce operational costs in the laundry industry.

Stylish appearance with easy operation, strengthening the hotel's brand image.

Xinye's RFID laundry tags are designed to endure high temperatures and exposure to chemicals, ensuring reliable performance through numerous wash cycles, making them ideal for industrial laundering applications.

Yes, Xinye offers customization options for RFID laundry tags, including size, material, and frequency, to meet the specific needs of different industries and applications.

Our RFID laundry tags are compatible with various technologies and can be seamlessly integrated into existing laundry systems, facilitating efficient tracking and inventory management.

Xinye's RFID laundry tags are built for durability, capable of withstanding numerous laundering cycles without compromising functionality, ensuring long-term tracking reliability.

Yes, our RFID laundry tags are versatile and can be used to track various textiles, including linens, uniforms, and garments, across different industries.

Absolutely, our RFID laundry tags enable real-time inventory tracking, providing accurate data that enhances operational efficiency and reduces manual errors in textile management.